-

Đó là mô hình “Thu gom rác thải nhựa từ biển vào bờ, biến rác thành tiền” của Hội Liên hiệp Phụ nữ (LHPN) xã Bình Minh, huyện Thăng Bình (Quảng Nam) triển khai thực hiện. Mô hình này không chỉ góp phần bảo vệ môi trường sinh thái biển mà còn hỗ trợ sinh kế và trợ giúp khó khăn đối với người nghèo của địa phương.

-

(TN&MT) - Đó là yêu cầu của Thứ trưởng Bộ Tài nguyên và Môi trường (TN&MT) Võ Tuấn Nhân tại Hội thảo “Đầu tư xử lý chất thải nhựa Việt Nam, cơ hội và thách thức” do Quỹ Bảo vệ Môi trường Việt Nam và Hiệp hội nhựa Việt Nam phối hợp tổ chức vào ngày 5/10, tại TP.HCM. Hội thảo có sự tham gia của các cơ quan quản lý nhà nước, các chuyên gia, nhà khoa học trong nước và quốc tế, đặc biệt là sự tham gia của đông đảo các doanh nghiệp hoạt động trong lĩnh vực sản xuất nhựa và tái chế chất thải nhựa.

(TN&MT) - Đó là yêu cầu của Thứ trưởng Bộ Tài nguyên và Môi trường (TN&MT) Võ Tuấn Nhân tại Hội thảo “Đầu tư xử lý chất thải nhựa Việt Nam, cơ hội và thách thức” do Quỹ Bảo vệ Môi trường Việt Nam và Hiệp hội nhựa Việt Nam phối hợp tổ chức vào ngày 5/10, tại TP.HCM. Hội thảo có sự tham gia của các cơ quan quản lý nhà nước, các chuyên gia, nhà khoa học trong nước và quốc tế, đặc biệt là sự tham gia của đông đảo các doanh nghiệp hoạt động trong lĩnh vực sản xuất nhựa và tái chế chất thải nhựa.

Large old trees give so much. They provide beauty and shade, raise property values, remove pollutants, and have even been shown to bolster mental health.

However, their sprawling roots tilt up concrete sidewalks, posing physical risks in the form of tripping hazards that can open cities to costly lawsuits.

What’s an environmentally conscious and legally liable community with mature trees to do?

In Logan, Utah, they are looking beyond the age-old solution of getting out the chainsaws. Instead, they have replaced some buckling slabs of cement with paving tiles made from 100 percent recycled low density polyethylene. Called Terrewalks, the 24-inch-by-30-inch tiles are 35 pounds each and can be easily removed to trim tree roots and then set back in place.

Not only have Terrewalks saved trees in at least 200 U.S and Canadian cities, the raw materials for the synthetic squares come from some of the lowest grades of LDPE. We’re talking dirty agricultural film that previously had little if any demand, as well as by-products from composite wood deck maker Trex Co. Inc. And, that solves another issue of what to do with some problematic post-consumer waste.

Terrewalks are sold by Terrecon Inc., which is based in Fountain Valley, Calif. CEO and founder Lindsay Smith got the idea for the business in 2001 after seeing red Xs painted on 26 ficus trees marked for removal in her California neighborhood. Her company started out using rubber for the flexible sidewalks but added recycled plastic in 2007.

The raw materials, such as plastic wrap used to bale hay for dairy cows, are converted into Terrewalk tiles through a process called thermo-kinetic technology, which, unlike injection and extrusion molding, does not require plastic to be clean, sorted or pelletized.

“It’s a form of compression molding that allows the plastic to be coarse and diverse,” Smith said in an email. “This contributes to the concrete-like appearance of Terrewalks.”

Terrecon has partnered with three different manufacturers in the western United States to date. But starting in April, Lehman & Sons Enterprise LLC of Bristol, Ind., will exclusively handle production. Smith said a central location is needed as plastic sidewalks make inroads across North America.

“This is part of the evolution of the company and a desire to lower costs of the products,” she said. “Being in the central U.S. will reduce the cost of shipping, but most importantly, it’s because there is so much ag plastic in the Midwest. Before, we were spending a lot on moving plastic.”

Root of the problem

Logan, a college town in northern Utah, has won Tree City USA awards for 28 years and counting, so when some giant willows, cottonwoods and London planetrees were facing the ax in 12 residential and high-traffic areas, some people cringed.

“Public safety is at the top of the list for the city of Logan, so the tree often loses out when these conflicts arise,” Megan Dettenmaier, the forestry extension educator at Utah State University, said in an email.

She and her colleague had heard about plastic sidewalks being used to leave problem trees in place and they checked into it. Dettenmaier talked to local officials in Alaska and Wisconsin and after getting positive reviews she applied for and received an $8,000 state grant to try Terrewalks in Logan. The city matched the grant with $10,000 and provided the labor to install the tiles.

“Trees in Logan will be spared, and if they become a problem again, the tiles can be uplifted, problem roots can be trimmed, and the same tiles can be re-laid,” Dettenmaier said in an email. “This is a unique product that reduces waste, helps cities retain mature trees, and creates safe walkable sidewalks. And, even better, the construction can usually be completed in a day.”

Plastic sidewalks are more expensive than concrete — initially, she added.

“But there are high costs associated with the business-as-usual model, where trees that have buckled sidewalks are removed, new sidewalks are poured and new trees are planted, only to have the cycle repeated in the future when that new tree becomes a problem again.”

Terrewalk pavers, which have a 20-year warranty, were installed in Logan last summer and are being monitored as to how they hold up to heat, harsh winters and different snow removal methods.

“Weather is the biggest unknown at this time,” Dettenmaier said.

Branching out

While some municipalities consider themselves in the test stage for Terrewalks, Smith said the product is “tried and true” and gaining popularity for commercial, corporate and university applications. The plastic tiles can replicate the look of granite, marble and stone and they are promoted as slip-resistant and compliant with the American with Disabilities Act

“They’ve been installed throughout the country since 2008,” Smith said. “They are unbreakable — even when they are frozen solid. They’re long lasting and pretty much indestructible. … They are also safer and more comfortable to walk or run — or fall — on.”

Terrecon recently announced that its paving tiles also will be specified for tee pads by Houck Designs, which it says is the No. 1 disc golf designer in the world, because they are easy to install, durable and cleanable.

The paving tiles also qualify for green building credits because they are made of recycled material and resist sunlight, which reduces the heat-island effect brought on by cement. In addition, the polymer pathways can play a role in storm water management. The bottom sides of Terrewalks have channels that serve as reservoirs and can hold 2.3 gallons of rain per paver. That allows storm water to slowly percolate to the soil below.

“Certainly preserving and maintaining the urban forest is its main benefit, but capturing storm water is a very big consideration these days,” Smith said.

Terrewalks also are good for construction sites, where they can’t be marred by heavy equipment like poured concrete, she added.

With the benefits plastic sidewalks offer, Terrecon is on the path to wider acceptance but will it change our landscape underfoot? Smith said displacing concrete as the main material for sidewalks will take a paradigm shift.

“The greatest challenge is overcoming the habitual use of concrete for sidewalks,” she said. “The infrastructure for concrete is highly evolved with contractors, installers, internal and external relationships, and red tape. Change meets resistance — even when everyone knows that concrete breaks, causing trip hazards and lawsuits, and it cannot coexist with the urban forest.”

Nguồn: plasticsnews.com

- Khó khăn của ngành nhựa trong năm 2013

- Giá nhập khẩu chất dẻo nguyên liệu từ thị trường Thái Lan tăng

- Nhựa sinh học từ thực vật an toàn với môi trường

- Ý tưởng triệu USD từ nắp cốc cà phê

- XUẤT KHẨU SẢN PHẨM NHỰA TỚI THỊ TRƯỜNG MỸ TĂNG 12.8%

- Dùng đồ nhựa đúng cách để bảo vệ sức khỏe

- Diễn biến thị trường Nhựa 2 tuần cuối tháng 8/2013

- Diễn biến thị trường Nhựa và chất Dẻo 2 tuần đầu tháng 8/2013

- NHẬP KHẨU CHẤT DẺO NGUYÊN LIỆU ĐẠT 2 TRIỆU TẤN

- KỶ LỤC THẾ GIỚI: SỢI DÂY TẾT TỪ NẮP CHAI DÀI NHẤT

- Xuất khẩu sản phẩm nhựa tới Hoa Kỳ tiếp tục đạt mức cao

- Việt Nam khó tăng trưởng tốt giữa một châu Á suy giảm

- HẠT NHỰA PE

- Chọn loại nhựa nào để ép khuôn

- Có thể sản xuất nhựa sinh học từ vỏ hạt điều

- GIÁ PP, PE DIỂN BIẾN TRÁI CHIỀU TẠI CHÂU Á VÀ CHÂU ÂU

- Tình hình xuất khẩu sản phẩm nhựa tuần từ 18/10 - 25/10/2013

- Doanh nghiệp Ấn Độ có nhu cầu nhập khẩu sản phẩm nhựa - PVC Flex Banner

- Quốc hội chốt kinh tế 2014 tăng trưởng 5,8%

- Bảng phân tích SWOT ngành nhựa.

- CÁC CHÀO GIÁ HDPE MỨC THẤP NHẬP KHẨU TẠI THỔ NHỈ KỲ BIẾN DẦN

- Các thương vụ PVC tại Đông Nam Á đã đạt được với mức giá hạ

- “Việt Nam khó tăng trưởng tốt giữa một châu Á suy giảm”

- Lương tối thiểu tại doanh nghiệp tăng lên 1,9 triệu đồng

- Cuộc chiến khốc liệt giữa pallet gỗ và pallet nhựa

- Giá điện tăng dưới 10%, EVN được tự quyết

- THAM KHẢO GIÁ HẠT NHỰA PP TUẦN 46 - 47/2013

- Thị trường PE Việt Nam

- Hãng NEC sản xuất nhựa sinh học từ vỏ hạt điều

- CPI cả nước tháng 11 tăng 0,34%

- Lương, thưởng Tết cho người lao động giảm

- Thị trường PVC Việt Nam

- EVN thu hơn 7 tỷ đôla tiền bán điện

- Đề xuất tỷ giá linh hoạt hơn

- GIÁ CẢ PP, PE TĂNG TẠI THÁI LAN

- Thị trường PE Việt Nam tuan 49

- SEA Games 27: Đoạt 40 HC Vàng, Việt Nam qua mặt Myanmar

- Kịch bản nào cho vĩ mô 2014?

- HLV U23 Việt Nam xin lỗi vì đã làm CĐV thất vọng

- SEA Games ngày 19/12: Chàng thượng úy nghèo lại giành HC Vàng

- Bội thu HC Vàng, Việt Nam vững vàng thứ hai

- CUNG KHAN HIẾM KHIẾN NGƯỜI BÁN TÌM CÁCH NÂNG GIÁ PE THÊM TẠI Ý

- Festival Hoa Đà Lạt lần thứ 5 (2013 – 2014)

- Sóng đánh toàn bộ xác 7 học sinh vào bờ biển Cần Giờ

- Thủ tướng New Zealand: Việt Nam phát triển vượt bậc như rồng

- "Chênh vênh" thưởng Tết giáo viên

- Nguyên liệu nhựa tăng 30 %

- Vụ nổ đài cát-xét: Món quà sinh nhật bí ẩn

- Land Rover Defender độ nội thất hạng sang

- Tác giả Flappy Bird bất ngờ tuyên bố gỡ trò chơi

- Công Ty TNHH MTV Nhựa Thiên Quốc bán hạt nhựa nguyên sinh

- TỔNG QUAN NGÀNH NHỰA THẾ GIỚI

- Ajinomoto Việt Nam đạt Doanh nghiệp Kinh tế xanh 2013

- Tổng quan :Thị trường PP Việt Nam tuần 11- 2014

- Doanh nghiệp: Indonesia sẽ không áp dụng thuế chống bán phá giá PET

- Mỹ rà soát thuế chống bán phá giá túi nhựa PE của Việt Nam

- Nhập khẩu PET, PP và PVC tăng mạnh từ thị trường Đài Loan

- Thị trường PP, PE Việt Nam gia tăng do nguồn cung thấp

- Cuộc chiến thầm lặng ở ngành nhựa

- Quả bóng nhựa Trung Quốc chứa chất độc hại

- Thông báo

- Công Ty Cổ Phần Visual Plastic đang nhận gia công sản phẩm

- Công Ty Cổ Phần Visual Plastic nhận gia công sản phẩm

- Triển lãm nhựa TAIPEI PLAS 2014

- Xây dựng hệ thống sedex tại Công Ty Cổ Phần Visual Plastic

- DOANH NGHIỆP NGÀNH NHỰA: ĐANG CÓ NHIỀU LỢI THẾ

- Nguồn nắp nhựa trong tương lai

- Quy hoạch phát triển ngành nhựa Việt Nam đến năm 2020

- Việt Nam xuất khẩu hạt nhựa PP đầu tiên ra thị trường

- Xuất khẩu nhựa sẽ đạt kỷ lục 1 tỷ USD

- Hãng NEC sản xuất nhựa sinh học từ vỏ hạt điều

- Trung Quốc chào tăng giá nhựa PP

- Tình trạng ế ẩm kéo dài tại thị trường PS Trung Quốc và Đông Nam Á

- Việt Nam nhiều cơ hội xuất nguyên liệu nhựa sang Thổ Nhĩ Kỳ

- Nhựa gia dụng Việt Nam bỏ lỡ phân khúc cao cấp

- Nước ép đóng hộp 100% thiên nhiên?

- Arburg sẽ tổ chức sự kiện “Những Ngày của Bao bì” lần đầu tiên

- Trái đất ra sao nếu túi nilon biến mất?

- Mỹ: Tiểu bang California sẽ cấm dùng túi nylon

- Công nghê mới tự động phân loại các loại nhựa để tái chế.

- Thị trường polymer Châu Âu bắt đầu ổn định lại trong tháng 10

- Plastic caps essential to health, beauty end market

- Recyclers see progress on shrink-sleeve labels for PET bottles

- Ngành nhựa hướng tới sản phẩm thân thiệt

- Tái chế lọ nhựa thành chậu hoa nhỏ xinh cực bắt mắt

- Biến áo sơ mi thành áo váy cho bé thật đơn giản

- Doanh nghiệp ngành nhựa được chủ động lựa chọn lãi suất vay vốn

- TPC, DPC: 2 doanh nghiệp ngành nhựa báo lãi quý 1/2014

- Hướng đi cho ngành nhựa tái chế

- Hướng đi nào cho M&A ngành nhựa?

- Chưa bao giờ DN lại thờ ơ với vốn tín dụng như hiện nay

- EU điều tra về túi nhựa nhập khẩu từ Trung Quốc

- German export sales strong, push for energy savings continues

- Giá dầu thế giới giảm mạnh

- CHẤT LIỆU NHỰA AN TOÀN

- NHỮNG KÝ HIỆU NHỰA THƯỜNG DÙNG (nguồn tupperware)

- Nhiều công nghệ tiên tiến nhất cho ngành nhựa và cao su VN

- Cơ hội đầu tư đổi mới công nghệ

- Nhiều công ty đa quốc gia đang chuyển đầu tư sang Việt Nam

- Unifi joins UNC to support recycling on campus

- SIPA collaborates on innovative lightweight pressure vessel liners made from PET

- Nhựa gia dụng: Hàng Việt chiếm lĩnh thị trường

- Tạo lợi thế cho xuất khẩu sản phẩm nhựa

- Plastic Feedstock Supply

- Winners of the 2014 Innovation in Plastics Recycling Awards announced

- Triển lãm thiết bị công nghiệp ngành nhựa và cao su

- Recycled soft drink bottles used for environmentally friendly stroller

- Xuất khẩu nhựa tăng trưởng ổn định

- Resin Pricing

- Công nghệ tái chế túi plastic thành nhiên liệu

- Parx Plastics Wins World Technology Award for Materials

- Kiến nghị giữ mức thuế 0% cho chất hóa dẻo DOTP nhập khẩu

- Domestic demand for plastics industry goods grew 6.5 percent in 2013

- Vật liệu mới từ thiên nhiên thay thế chất dẻo

- Tìm hướng phát triển công nghiệp hỗ trợ ngành nhựa – cao su TP. HCM

- Sipa acquires Automa’s PET bottle business

- Plastics save energy

- Giá dầu tiếp tục rơi về sát 55 USD/thùng

- Tổng quan ngành hàng nhựa Việt Nam - Phần 2

- Thị trường cung cấp nguyên liệu nhựa cho Việt Nam 2 tháng đầu năm 2014

- Merry Christmas and Happy New Year!!!

- Giá xăng dầu sẽ giảm trong nay mai?

- Tổng hợp dụng cụ sáng tạo được tái chế từ vỏ chai nhựa cũ (P.1)

- Plastic packaging gaining momentum in Mexico

- Nhựa tự hủy chế từ vỏ trấu

- Tết 2015: Tiền lì xì USD bằng nhựa hút khách

- Giá dầu tiếp tục lập đáy mới, thấp nhất kể từ tháng 4/2009

- Ngành nhựa - cao su: Phát triển trong thế khó

- Những quan niệm sai lầm về phá giá VND

- VN xếp thứ 5 trong các nước đầu tư nhiều vào Campuchia

- Từ 16h30 chiều 6/1, giá xăng giảm 310 đồng/lít

- Ngành nhựa lạc quan

- Mục tiêu xuất khẩu của Công nghiệp nhựa Việt Nam

- Lạ mắt với thực đơn bằng... nhựa của nhà hàng Nhật Bản

- ĐỂ NGÀNH NHỰA PHÁT TRIỂN BỀN VỮNG

- Người tiêu dùng vẫn thiệt thòi dù xăng dầu giảm giá sâu

- KINH TẾ 80% nguyên liệu ngành nhựa phải nhập khẩu

- Tái chế chai nhựa thành giấy

- Lợi ích cho nền kinh tế vượt xa mức hụt thu khi giá dầu giảm

- Quy hoạch phát triển ngành nhựa đến năm 2020

- “Giá dầu có thể giảm xuống mức 20 USD/thùng”

- Tiền lương 2015 và tin vui đầu năm mới

- PVN sẽ không đầu tư mạnh vào khai thác dầu

- Cơ hội từ giá dầu giảm

- Cơ hội lớn cho ngành công nghiệp nhựa

- Lương tối thiểu phải tăng từ 18-19% mỗi năm

- Bỏ tiền tỷ mua hạt nhựa, bị TQ lừa bán đá dăm

- Thực hư tin giá xăng sắp tăng mạnh?

- Tăng giá điện, doanh nghiệp lại lo

- Giá xăng tăng hơn 1.600 đồng từ 15h chiều nay

- Thách thức ngành bao bì trong năm nay

- Nhựa đường làm từ cây xanh

- Việt Nam sắp trở thành “con hổ kinh tế mới” của châu Á

- Mẹo đánh bay mùi hôi của đồ nhựa cực đơn giản

- Dưa hấu Quảng Nam bị ép giá 1.000 đồng/kg tại ruộng?

- Đến thời dân Việt xài 100% ôtô nhập giá rẻ?

- Công nghiệp ôtô - 20 năm vẫn một ngã ba đường

- Masan Group bất ngờ “quay lại” sở hữu Proconco

- Chính sách mới có hiệu lực từ tháng 5/2015

- TỰ TIN DÙNG TUPPERWARE

- CÁCH PHÂN BIỆT MỘT SỐ LOẠI NHỰA THÔNG DỤNG

- KỸ THUẬT THỔI NHỰA TẠI VIỆT NAM

- Giá xăng tăng kỷ lục(5/5/2015)

- Doanh nghiệp đề nghị tăng giờ làm thêm, Bộ Lao động phản đối

- Hơn 320 doanh nghiệp tham gia triển lãm ngành nhựa và cao su

- Bộ Công Thương vừa có quyết định tăng giá xăng dầu từ 20h 20.5.2015

- Ấn tượng gạo, tỏi trong đàm phán thương mại với Hàn Quốc

- Samsung ngừng sản xuất TV tại Thái Lan

- Nguy hiểm khi dùng đồ nhựa đựng thực phẩm

- Bí quyết để có được thành công trong khâu bán lẻ

- Doanh nghiệp VN thêm cơ hội tiêu thụ hàng hóa

- KINH TẾ “Nhà đầu tư Hoa Kỳ háo hức ở VN là chưa từng thấy”

- Giá dầu sẽ ở ngưỡng 60 USD/thùng trong năm 2015 và 2016”

- Nhật Bản trồng siêu cao lương tại Việt Nam

- 10 nguyên tắc thành công của vua thép Andrew Carnegie

- 10 phát ngôn để đời về nghệ thuật đàm phán

- Bốn nguyên tắc khởi nghiệp kinh doanh

- Nói thật hay để bán hàng thật dễ

- Năm chiến lược để có thể đo lường hiệu quả marketing

- Thế nào là một quốc gia vỡ nợ

- Mỹ chính thức thông qua TPA

- Ngân hàng Nhà nước mua lại GPBank với giá 0 đồng

- Hiến kế xây Trung tâm Hội chợ Triển lãm Quốc gia

- Hàng loạt dự án đầu tư lớn rút khỏi VN: Chớ thấy tỷ đô mà hoa mắt

- Cục Thuế TP HCM xin lỗi doanh nghiệp bị bêu tên oan

- Trở thành giám đốc marketing dù không có bằng đại học

- 4 nguyên tắc ra quyết định của Richard Branson

- ĐỔI 35 TRIỆU TỶ ĐÔLA ZIMBABWE LẤY 1 USD

- Doanh nghiệp được giảm 420 giờ nộp thuế

- VCCI: 30% doanh nghiệp chi tiền 'lót tay' cho cán bộ thuế

- Doanh nghiệp "ngấm đòn" tỷ giá

- Thu nhập công nhân khó tăng theo lương tối thiểu

- Chính sách tiền tệ Việt Nam thêm một phen thử thách

- Cổ phiếu BIDV bị bán mạnh sau khi rời danh mục Vietnam ETF

- 14 lời thoại phim truyền cảm hứng cho doanh nhân

- Những sai lầm tài chính dễ mắc phải khi khởi nghiệp

- Tập đoàn Singapore đầu tư 13 triệu USD vào nước chấm Nam Dương

- Xuất khẩu gạo tháng 10 giảm kỷ lục

- Các nhà rang xay thế giới cảnh báo cà phê Việt Nam

- Gần 300 doanh nghiệp dự triển lãm nhượng quyền thương hiệu

- Masan muốn mua nước khoáng Quang Hanh

- Người Việt dè dặt chi tiêu

- Sản xuất nắp phi 28 (cổ 1810 & 1881)

- 3 bí quyết làm giàu của Warren Buffett

- Doanh nghiệp rót hơn 625 triệu USD ra nước ngoài sau 10 tháng

- Ngành nhựa đối mặt với nhiều thách thức hội nhập

- 11 điều cần biết về FTA Việt Nam - EU

- Ngành nhựa trước sức ép hàng Thái

- Công ty nhựa hàng đầu Thái Lan sắp mở thêm chi nhánh ở Việt Nam

- Để đứng vững trước hội nhập

- Kiếm bộn tiền từ những thứ bỏ đi

- Nhập khẩu điều thô của Việt Nam tăng mạnh

- Dành 10 triệu USD xây dựng nhà máy sản xuất túi nhựa phân hủy

- Xuất khẩu nhựa tăng mạnh

- Quy hoạch phát triển ngành nhựa đến năm 2020

- Nhận biết các loại nhựa để sử dụng đúng cách

- Nhu cầu thị trường PVC toàn cầu sẽ gia tăng trong 6 năm tới

- Nới điều kiện nhập khẩu máy móc cũ

- 80% nguyên liệu ngành nhựa phải nhập khẩu

- Doanh nghiệp sản xuất nhựa: Tự bán hoặc bị mua

- Giá dầu khép tuần ở mức thấp nhất kể từ cuộc khủng hoảng 2008

- Giáng Sinh 2015 An Lành!

- Kinh tế Việt Nam ra sao khi giá dầu về 30 USD một thùng

- USD ngân hàng kịch trần, tự do chạm 22.740 đồng

- Ngành nhựa loay hoay tìm nguyên liệu

- Việt Nam xuất khẩu hạt nhựa PP đầu tiên ra thị trường

- Doanh nghiệp thêm gánh nặng chi phí đầu năm 2016

- Không khí Noel tràn ngập thủ đô

- Tổng quan ngành hàng nhựa Việt Nam - Phần 2

- Berry Plastics expanding in Tennessee

- Oil, gas prices continue to make economic news

- Rotomolding trends for 2016

- Nhập khẩu polyethylene tăng 15-18% trong 2016

- Kịch bản nào cho giá dầu năm 2016?

- Cabin crew, doors to plastic please

- Ngành nhựa: Tiềm năng và nỗi lo chi phí

- EuroPlast back in business under new owner

- Giá xăng dầu tiếp tục giảm, thấp nhất trong vòng 5 năm qua

- Hội nhập thành công xoá nỗi đau tụt hậu

- Năng suất lao động: Vì sao Việt Nam luôn đứng cuối bảng?

- Techcombank ra mắt sản phẩm chuyên biệt cho doanh nghiệp ngành nhựa

- Dự cảm kinh tế Việt Nam 2016

- Giá dầu xuống đáy 12 năm

- PET bottle resin down 1 cent

- Recycler wins approval for food-contact polystyrene

- Doanh nghiệp công nghiệp hỗ trợ “ngóng” ưu đãi

- Ngành nhựa thiếu quy hoạch

- Khó khăn trong phát triển ngành nhựa

- Tập đoàn Ajinomoto hướng đến top 10 toàn cầu

- Hàng Việt thua đứt hàng Thái, Lào, Campuchia?

- Ngành nhựa Việt Nam đang chịu sức ép thâu tóm từ doanh nghiệp ngoại

- Cuộc chiến M&A và cạnh tranh trên sân nhà của ngành nhựa

- Tin tức Áp lực thuế đè nặng doanh nghiệp nhựa

- Sức hút của ngành nhựa trong năm 2016

- Thực trạng ngành nhựa Việt Nam

- Xăng dầu đồng loạt tăng giá từ 19 giờ ngày 5.12

- Lock&Lock vào top 10 sản phẩm, dịch vụ Tin & Dùng 2016

- 6 hiệp hội muốn 'truy' đơn vị đứng sau khảo sát nước mắm

- Xăng trước áp lực tăng giá mạnh hôm nay

- Ngành nhựa đang là “đích ngắm” của nhiều nhà đầu tư nước ngoài

- Doanh nghiệp ngành nhựa: Lạc quan hơn vào xuất khẩu 2017

- Doanh nghiệp nhựa năm 2017: Cẩn trọng với sự dòm ngó của người Thái

- WB nâng dự báo giá dầu thế giới năm 2017

- Thủ tướng cấm công chức bỏ việc đi lễ hội sau Tết

- Kim ngạch xuất khẩu nhựa dự báo tăng trưởng 3,5 - 6%

- Cập nhật ngành nhựa- VCBS

- Giá xăng tăng lần đầu tiên trong năm 2017

- Chuẩn bị xây dựng cao tốc Bắc Nam qua 20 tỉnh, thành

- Xăng có thể giảm giá hôm nay

- Doanh nghiệp nhựa đẩy mạnh đầu tư nhằm tránh bị thâu tóm

- Doanh nghiệp dầu khí 'lách khe cửa hẹp'

- Masan nhận thêm 250 triệu USD từ đối tác ngoại

- Hà Nội tổ chức triển lãm quốc tế về công nghiệp nhựa, bao bì

- Các địa điểm đi chơi dịp lễ 30/4- 1/5 tuyệt nhất miền Bắc

- Mexico chế tạo thành công nhựa từ hạt quả bơ

- Ngành nhựa đổi mới công nghệ sản xuất

- Việt Nam - Nhật Bản ký các hợp đồng trị giá 22 tỷ USD

- Visual Plastic XANH

- Giá xăng có cơ hội giảm ngày mai

- Công ty Á Mỹ Gia sắp về tay Earth Chemical với giá 1.800 tỷ đồng

- Triển vọng ngành nhựa 2017: Giá hạt nhựa PE, hạt nhựa PP, hạt nhựa PVC

- Nhìn ra cơm bằng nhựa, cải bắp

- Xăng tăng gần 600 đồng một lít

- Nhựa sinh học làm từ vỏ tôm

- 18 quốc gia tham gia triển lãm quốc tế công nghiệp nhựa và cao su 2017

- Giá xăng có thể tiếp tục tăng vào ngày mai

- Nhựa làm từ thực phẩm: Liệu có phải một ý tưởng hay?

- Nhiều doanh nghiệp hướng đến mục tiêu phát triển bền vững

- Xăng tăng hơn 400 đồng mỗi lít

- Masan muốn chi 1.700 tỷ mua toàn bộ Vinacafé Biên Hòa

- HỘI THI TAY NGHỀ 2017

- MERRY CHRISTMAS 2017

- THÔNG BÁO NGHỈ TẾT DƯƠNG LỊCH

- Algeria sẽ tạm ngừng nhập khẩu 851 mặt hàng kể từ tháng 1/2018

- Người Thái đã mua những gì ở Việt Nam?

- Doanh thu Kido tăng gấp đôi nhờ hợp nhất hai công ty dầu ăn

- Điện, xăng dầu đẩy chỉ số giá tiêu dùng tăng

- Công đoàn gửi tặng quà Tết Nguyên Đán năm 2017 đến CBCNV Nhà máy

- THÔNG BÁO NGHỈ TẾT NGUYÊN ĐÁN 2018

- Báo cáo thị trường hạt nhựa các tuần từ 01/01/2018 đến 13/01/2018

- Masan Consumer Holdings và Masan Consumer có tổng giám đốc mới

- Nhựa Việt Nam rộng đường xuất khẩu

- Lũ lụt cuốn trôi 43 tỷ mảnh nhựa ra biển.

- Giá PET tại Đông Nam Á duy trì tăng trong khi giá MEG giảm

- Kim ngạch xuất khẩu nhựa dự báo tăng trưởng 12-15%

- Xăng tăng gần 600 đồng một lít

- Doanh nghiệp nhựa yếu thế ở sân nhà

- Các nhà khoa học bước đầu tìm ra cách tái chế nhựa vô hạn lần

- Tăng trưởng GDP quý II dự báo dưới 5%, gần thấp nhất trong 13 năm

- Masan vào top 2 nhà sản xuất được chọn mua nhiều nhất

- Bảo vệ môi trường: Đức bác đề xuất đánh thuế bao bì nhựa đóng gói

- Nguyên liệu nhựa xuất khẩu chủ yếu sang Trung Quốc, giá rất rẻ

- Nguyên liệu nhựa xuất khẩu chủ yếu sang Trung Quốc, giá rất rẻ

- Polymer Marketing Vietnam khai trương công ty đầu tiên tại Việt Nam

- Starbucks tuyên bố ngừng sử dụng ống hút bằng nhựa

- Sản xuất nhựa sinh học từ rơm rạ

- Cảng Cái Mép tìm chủ nhân 4 lô hàng phế liệu nhựa quá hạn

- Hàn Quốc cấm sử dụng túi nilon dùng một lần tại các siêu thị

- Túi nilon làm từ vỏ tôm, cua và thực vật

- Tại sao ngành nhựa không tận dụng nguyên liệu trong nước?

- Biến rác thành tiền

- Kho nhựa tái chế ở Hưng Yên chìm trong khói lửa

- Cháy lớn xưởng sản xuất đồ nhựa ở Sài Gòn

- Ngành tái chế nhựa phải ưu tiên sử dụng nguyên liệu trong nước

- Nhật Bản cam kết giảm rác thải nhựa

- Chỉ được nhập khẩu phế liệu nhựa đã làm sạch tạp chất

- Nhận biết các loại nhựa và khả năng tái chế chúng

- Liên Hiệp quốc: Thế giới có thể cắt giảm 80% ô nhiễm nhựa vào năm 2040

Copyright © 2013

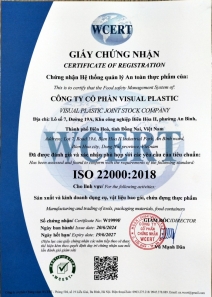

Công Ty Cổ Phần Visual Plastic – Visual Plastic Joint Stock Company

Địa chỉ: Lô số 07, Đường 19A, KCN Biên Hòa II, P. An Bình, TP. Biên Hòa, Tỉnh Đồng Nai

Điện thoại: (84-0251) 3992 284 - Fax: (84-0251) 3992 287

Hotline: 0933.500.063 - 0903.608.012 (Mr. Sơn), 0901.554.367 (Ms Thu Mai)

0799518769( Ms.Lê Mai)

0799518769( Ms.Lê Mai)